Quality & Sustainability

Quality

Quality is much more than metrology – the science of measurement. It is ensuring all processes in the organization have minimal variation and work together as a system towards a unified goal – customer satisfaction.

Quality Policy

At PES we utilise the system approach to ensure your goal is met. Customer requirements correctly defined, research and development, competent suppliers, locked-down process parameters, preventative maintenance, in-process validation, calibration, leadership, employee development and training, internal audits. All these pieces of our system come together to maximize quality and minimize waste and total cost.

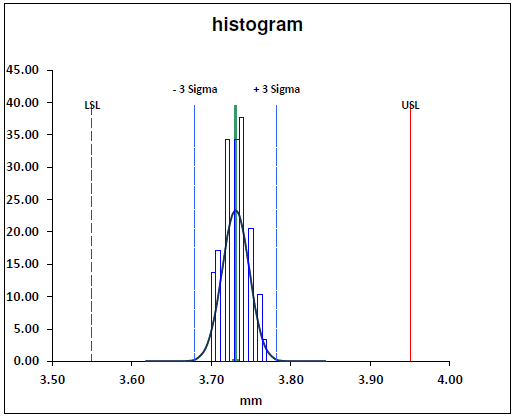

It is much more effective and cheaper to design in quality than to inspect out defects. PES use proven quality tools including FMEA, flow diagrams, control charts, histograms, fish-bone diagrams to create a manufacturing process that is in control, has minimal variation and the shortest flow from start to finish. This means your products will be just as effective from the very first shot to years in the future and the cost savings are passed on to you.

At the core of PES is leadership and business wide data from all our processes which allows us to improve our service and capabilities. We monitor and improve on-time delivery, internal scrap, machine downtime and many more to increase customer satisfaction. Through our systems we are able to view metrics on an overall level and drill down to individual production lines to focus on the vital few.

“The consumer is the most important point on the production-line.”

– William Edwards Deming

Plastic Engineering Solutions Ltd is committed to managing its business in a safe, quality manner. This commitment extends to ensuring that customer, statutory and regulatory requirements are met at all times. It is further committed to set, measure and monitor quality objectives in order to continually improve its performance. These goals are communicated to all its employees.

The various processes and activities undertaken are written in the procedures and these are readily available to all employees. The procedures themselves are kept under review by the Directors by means of the non-conformance control, auditing and management review process. These processes maintain the suitability of the existing system and provide a means of implementing improvements on a continual basis.

This policy is itself kept under continuous review.

Sustainability

At PES we take sustainability very seriously and it forms the frontispiece of all job descriptions to be diligent with and caring of our environment.

Some of our sustainability initiatives include:

- Certification to ISO14001, achieved Nov 2020 to enhance our Environmental Management System.

- Recycling all cardboard and jazz PE by investment in baling

- Power consumption 10% reduction target

- Monitoring screens in place measuring power consumption to aid target achievement.

- Studying machine settings for reduction in power opportunities

- Investigating the feasibility of replacing water chillers with alternative cooling systems

- Carbon reduction by 10% target

- Machine monitoring to provide accurate carbon usage to help achieve business target reduction as a percentage of sales / parts manufactured

- Alternative power sources being investigated such as turbines & solar

- Recycling waste plastic

- A key project for PES in 2021 is the production of EV chargers for new homes inline with government guidelines. With this project in mind, the PES motor fleet will be converted to electric

- 2 company cars have been changed to electric so far in 2021

- Company vans are planned to be replaced 1/year

- End of Life Disposal – The majority of our products are technically engineered multi-use products. By ensuring that our clients requiring new product have identified the type of plastic being used with the appropriate recycle logo at the design stage, we provide the opportunity for the correct recycling at the end of the product lifecycle.

- We aim to help all clients to consider their product end of life and where possible to design new products for ease of dismantling and recycling

- Paper usage is minimised and all data stored electronically with a robust back-up mechanism in place

- Used ink cartridges are collected and removed from site by a recognised collection agency for recycling.

- All electrical components are segregated and disposed into the correct recycling stream by our registered waste specialist.

- All waste wooden pallets are collected and recycled by our registered waste specialist, many returning directly to use

- Regular servicing of heating equipment to reduce risk of inefficiency

- When buying we always firstly consider local sourcing, quantities delivered & sustainable packaging

We review our sustainability program as part of Management Review with new initiatives and ideas discussed and implemented, once approved.